What should be know when choosing airless nozzles?

Nov 29, 2022

What should be know when choosing airless nozzles?

Nov 29, 2022

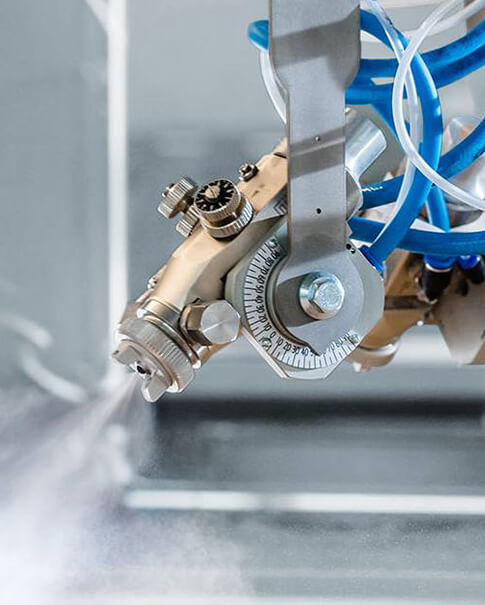

Airless spray machines are mainly used for spraying materials such as anti-corrosion and fire protection materials, epoxy resins, or emulsion paints. When choosing airless spray tips, we need to understand the spray width and flow rate, the nozzle flow rate is the size of the calibre.

There are generally three types of nozzles, standard, finishing and abrasion resistant, indicated by the English symbols LTX (standard), FFT (finishing) and GHD (abrasion resistant), with the coded numbers introducing the spray width and aperture data.

According to their needs, consumers can choose the model you want to buy, the following are the things we need to pay attention to when buying airless sprayer nozzles.

Firstly, when the airless paint sprayers is used for spraying emulsion paint, in order to ensure the efficiency of the construction and the thickness of the emulsion paint, it is best to use a standard type of nozzle with a five-inch radius and a 0.0017-inch diameter as the best option. When spraying the corners of the walls, it is necessary to switch to a nozzle with a relatively small spray width. When painting external walls, we can use a nozzle with a spray radius of twelve inches, which will increase efficiency. However, as the spraying range becomes larger, it is best to choose a larger spraying machine to ensure uniform thickness in order to ensure the quality of the spraying.

Secondly, when paint spraying machine spraying oil-based paint, we need to pay attention to the characteristics of the paint, oil-based paint density is low, strong liquidity, when the spray width is large, easy to cause the paint hanging, this time we had better use the finishing type of nozzle, this type of nozzle atomisation effect is better, can be more liquid paint spraying more evenly, in reducing the wear and tear on the nozzle at the same time to extend the use of the nozzle time.

Thirdly, when using the high pressure paint sprayer to spray fireproof and anti-corrosive materials, we need to use the standard type of nozzle, as these spraying materials contain granular substances on the nozzle wear and tear is more serious, so here we still recommend that you use the wear-resistant nozzle. When spraying anti-corrosion materials, we need to consider the problem that the thickness of the anti-corrosion material sprayed is relatively heavy, it is best to use a larger diameter nozzle when choosing a nozzle, but for steel structure of anti-corrosion materials, it is best to use a spray nozzle with a spray radius of 5 inches or less, so as to reduce the waste of paint and improve the use of paint.

What should be know when choosing airless nozzles?

Nov 29, 2022

What should be know when choosing airless nozzles?

Nov 29, 2022