What is the difference to use an airless paint sprayers?

Dec 13, 2022

What is the difference between the traditional manual application of emulsion paint or the use of airless sprayers for the application of walls?

Nowadays, there are many paint companies that offer a free painting service for homeowners, but they are often only responsible for painting or spraying, and often take a non-responsible attitude towards the base treatment of the walls. There are also many users who intend to buy their own paint and decorate themselves, and are considering whether it is better to apply manual brushing or machine spraying. If economic strength allows, or if you want to pursue a relatively high quality wall, of course, or choose airless spraying machine spraying is better, after all, the texture of the spray out is certainly brush out does not have. If you don't think it's worth buying the equipment once, you can also search online for airless spraying equipment for hire, which is better.

Because latex paint is a high-viscosity water-based paint, so spraying before the grassroots treatment of the wall and other important, or it will reduce the decorative effect of latex paint, which is why some paint company workers for free after the user painted the wall particles obvious, not as beautiful as the brochure up to the reason. After the base is cleaned and the surface is scraped with putty to smooth out the gaps and depressions, we can then paint on it.

As airless sprayers are relatively expensive, the average painter will not configure them, but of course it can't be said that there are absolutely none. Most people still paint the same way as in the early days, with a brush or a roller, plus a paint can directly on the wall, and because latex paint is highly viscous, it often needs to be diluted before it is applied. This directly reduces the elasticity of the emulsion paint, making it poorly dustproof and less decorative in the later stages of use, while easily producing cracks. In addition, traditional hand-brushing is time consuming and the utilisation rate of paint is relatively low, so I do not recommend it here.

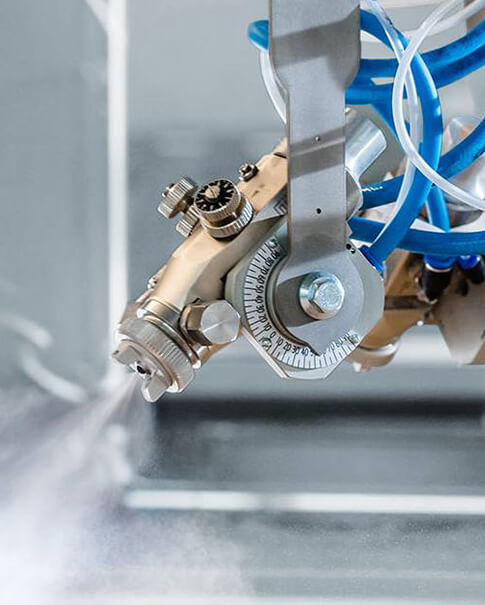

The walls are smooth as a mirror after spraying with an Electric airless putty texture paint sprayer spray machine, and the coating is so even and fine that you can't find any traces of paint on it, with a strong texture and fast working time, so it is a more efficient and high quality way of treating walls. But at a later stage if there is a problem with the wall and it needs to be repaired there is often a certain amount of trouble because basically the workers won't come over with an airless sprayer and spray it again for you, they can only use a brush, but this will leave obvious traces of brushing on the wall and the texture and effect of the two methods is certainly very different, so it is better for families with the financial means to have their own airless sprayer. The two methods are definitely different in texture and effect.