How to choose airless spray tips?

Oct 31, 2022

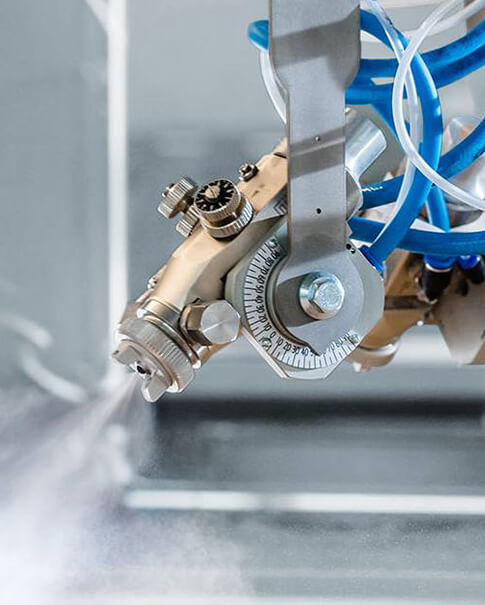

Airless spray machine spraying material composition materials mainly to anti-corrosion and fire protection materials, epoxy resin, or latex paint, in the choice of airless spray tips we have to think of the two aspects of the problem, one is the spray width, the other is the flow is also the size of the caliber.

Paint sprayer nozzles are generally divided into three types, respectively standard, finishing and wear-resistant, expressed in English symbols are LTX (standard), FFT (finishing), GHD (wear-resistant), the number of the code is the introduction of the spray width and calibre data. In accordance with their true wishes, consumers can choose the model you want to buy, and only through this method can they be assured that it is exactly what they need in reality. Here are some of the things we need to be aware of when buying a sprayer nozzle

When using airless paint sprayer to spray fireproof and anti-corrosive materials, we need to use a standard type of nozzle. As the granular material contained in these sprayed materials is a serious wear and tear on the nozzle, it is still recommended here that you use a wear-resistant nozzle. When spraying anti-corrosion materials, we need to consider the problem that the thickness of the anti-corrosion material sprayed is relatively heavy, it is best to use a larger diameter nozzle when choosing airless spray nozzle, but for steel construction of anti-corrosion materials, it is best to use a nozzle with a spray radius of 5 inches or less, which will reduce the waste of paint and improve the use of paint.

When the paint sprayer is used to spray emulsion paint, in order to ensure the efficiency of the construction and the thickness of the emulsion paint, it is best to use a standard type nozzle with a spray radius of five inches and a calibre of 0.0017 inches as the best option. When spraying the corners of the walls, it is necessary to switch to a nozzle with a relatively small spray width. When painting external walls, we can use a nozzle with a spray radius of twelve inches, which will increase efficiency. However, due to the larger spray range, it is best to choose a larger spraying machine to ensure a uniform thickness in order to ensure the quality of the spraying.

When paint spraying machine spraying oil-based paint, we need to pay attention to the characteristics of the paint, oil-based paint density is low, strong liquidity, when the spray width is large, easy to cause the paint hanging, it is best to use the finishing type of nozzle, this type of nozzle atomisation effect is better, can be more liquid paint spraying more evenly, in reducing the wear and tear on the nozzle at the same time to extend the use of the nozzle time.

The above describes so much about the use of spraying machine nozzle, the first contact with this equipment, many people will be confused, do not know what this machine is for, more do not know how to choose when using, in fact, this equipment looks huge, extremely complex, in fact, the working principle is still relatively simple, the general personnel after a simple training, can be skilled operation, save time and effort, the above I believe that you should have a certain understanding of this equipment, I hope that these introductions can produce a certain amount of help to the practical use of everyone.

What should be know when choosing airless nozzles?

Nov 29, 2022

What should be know when choosing airless nozzles?

Nov 29, 2022