How to use high pressure airless sprayer safely?

Sep 08, 2022

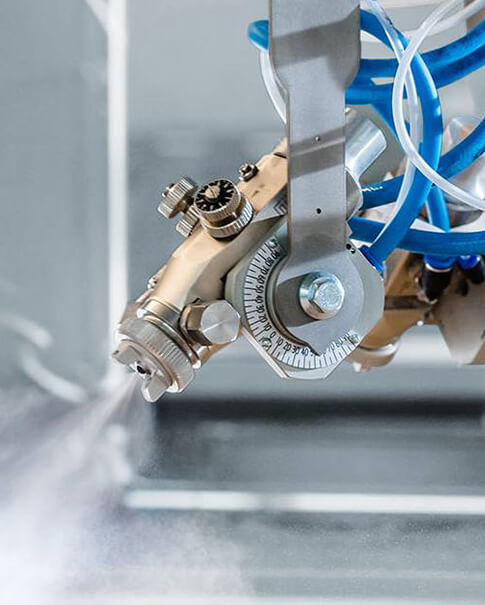

High pressure airless paint sprayers use a high-pressure plunger pump to pressurize the paint to 3000 PSI (210 kg/cm). The paint is delivered to the spray gun through a high-pressure hose, and the pressure is released through the nozzle to form atomization that creates a dense coating on the surface of the wall. Since no compressed air is required to atomize the paint, it is called airless spraying.

1. Before using this high-pressure airless spray machine, please make sure to read carefully and strictly comply with the requirements of this instruction manual.

2. The high-pressure airless sprayer must be placed smoothly and securely during the operation. The operator must pay attention to personal safety in the process of operation, if necessary, with a good protective cover and work cap after the operation.

3. The workplace should be well ventilated. The motor power cord and high pressure tube should not be stacked on the items or be stepped on, pressed etc. The high pressure pipe should be unobstructed on the way to be dragged during the operation to avoid damage to the high pressure pipe.

4. The voltage and frequency of the power supply used must be consistent with the nameplate on the motor.

5. Check carefully to confirm that the fasteners of the high-pressure airless sprayer are fastened securely before connecting to the power supply, and check to confirm that the pipe joints are connected securely.

6. To improve the service life of this high-pressure airless sprayer, the paint used should be clean, free of impurities and not deteriorated, and should be filtered through a filter of 80 mesh or more.

7. Pressure adjustment should not be greater than 200bar. If the high-pressure tube is replaced, the tube selected must be uniformly equipped by the paint sprayer manufacturer.

8. At no time is not allowed to point the gun at others, when operating to prevent the splash of paint on the operator's body, especially eye injury.

9. Don’t allow use the high-pressure airless sprayer spray acid, corrosive substances, toxic chemicals (such as pesticides, pesticides, etc.). Do not use banana water, dimethyl dumb and other solvents for spraying operations.during the operation, the operator should not eat food, do not smoke.

10. After the completion of the spraying operation, to unload the flow, unload the pressure, and then turn off the motor, and then immediately clean the parts of the paint flow through the cleaning solution, wash the residue, it is strictly prohibited to clean with boiling water.

11. When moving the airless sprayer, generally cut off the power supply, motor and plug are not allowed to contact with water and paint, keep the machine clean and dry.

12. The tools used in any fastening, adjustment and maintenance of this airless sprayer should be suitable and the operation should be standardized to prevent damage to the machine or the person.

13. Do not allow arbitrary changes to the structure of this airless sprayer. Do not use spare parts that do not meet the requirements.